Cold Heading Machine Manufacturers: Precision in Metal Forming

Cold heading machines are essential in the manufacturing industry for producing high-quality metal parts with precision and efficiency. These machines are widely used in automotive, aerospace, and fastener industries, among others. Manufacturers of cold heading machines play a crucial role in delivering advanced solutions for metal forming processes.

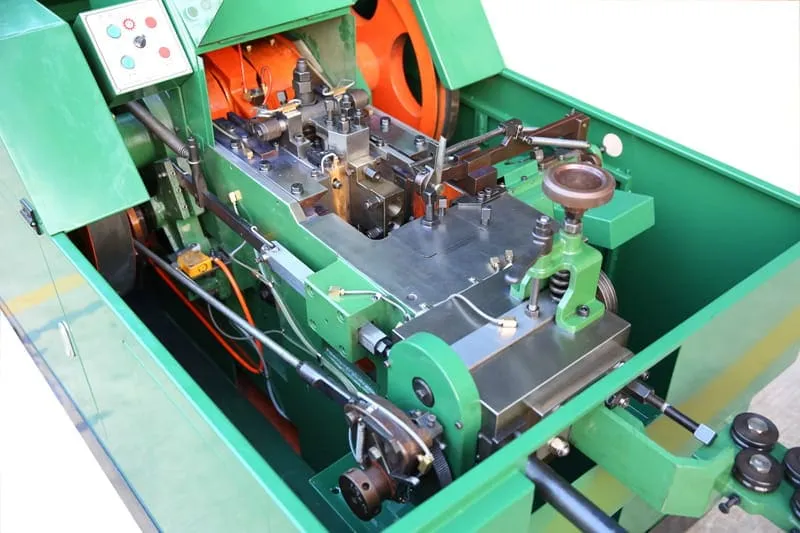

A modern cold heading machine in operation, showcasing its precision and efficiency in metal forming.

Key Features of Cold Heading Machines

Cold heading machines are designed to shape metal at room temperature, eliminating the need for heating. This process offers several advantages, including improved material strength and reduced waste. Below are some key features of these machines:

- High-speed production capabilities

- Precision in forming complex geometries

- Energy efficiency due to cold forming

- Minimal material waste

Leading Cold Heading Machine Manufacturers

Several manufacturers specialize in producing high-quality cold heading machines. These companies invest in research and development to enhance machine performance and meet industry demands. Below is a table highlighting some of the top manufacturers:

| Manufacturer | Location | Specialization |

|---|---|---|

| National Machinery | USA | High-speed cold heading machines |

| Sakamura | Japan | Precision cold forming machines |

| Hatex | Germany | Custom cold heading solutions |

Innovations in Cold Heading Technology

Recent advancements in cold heading technology have led to improved machine performance and versatility. Manufacturers are incorporating automation and smart controls to enhance productivity. Some notable innovations include:

- Integration of IoT for real-time monitoring

- Advanced lubrication systems for longer tool life

- Multi-station machines for complex part production

An automated cold heading machine with robotic arms, demonstrating the integration of advanced technology in modern manufacturing.

Choosing the Right Cold Heading Machine Manufacturer

Selecting the right manufacturer is critical for achieving optimal results in metal forming. Factors to consider include:

- Machine specifications and capabilities

- After-sales support and maintenance services

- Customization options

- Reputation and customer reviews

By partnering with a reputable manufacturer, businesses can ensure they receive reliable and efficient cold heading machines tailored to their specific needs.